diy c stand

DIY Tips: Making Your Own Poor Mans C-stand for $20!

Skip to contentFilmakerScott Egglestonloves low budget accessories. and is also an avid DIYer. On this video he looks at a way to easily and cheaply create a replacement for a light stand (C stand) which is extremely flexible and cost about $20 to make.

Buying a ready c-stand for holding your lighting and other accessories can easily cost you over a $100 (for example thisCowboystudio model on Amazoncosting just over $135). But if you are willing to go the DIY way you might be able to save quite a few bucks by buying a Mic Boom Stand which you can get for under $17 (see here on Amazon) which might not be the sturdiest thing in the world but with some help (sand bags water bottles etc.) you can make it stay in one place.

At this point you have the main unit and all you need to get is a few extra connectors that will allow you to attach any accessory to it such as a lighting. For example you can get aMic stand to 1/4 adapter(under $2) and a1/4 3/8 Light stud adapter(under $1) and finally aMini ball headthat will help your accessory get maximum movement on theMic Boom Stand. All in all you can make your own DIY C-stand replacement for just around $20 pretty cool isnt it?

Be sure to watchEggleston How to Make a DIY PVC Light Stand for Under $5.You can also check out many more interestingDIY photography projectshere on LensVid.

Iddo Genuth

Iddo Genuth is the founder and chief editor of LensVid.com. He has been a technology reporter working for international publications since the late 1990's and covering photography since 2009.Iddo is also a co-founder of a production company specializing in commercial food and product visual content.

Today we are taking a look at two recent batteries released by CameTV called the

Back in 2021, Sony introduced its fastest lens, the Sony 50mm f/1.2 GM lens. Today

Today we will be taking a look at three recent bags from iFootage the

Today we take a look at an innovative lens announced back in 2023 the

DIY Gear,Photo GearC stand,DIY,DIY C stand,Scott EgglestonIddo Genuth

This website uses cookies to improve your experience. We'll assume you're ok with this, but you can opt-out if you wish. Cookie settingsACCEPTPrivacy & Cookies Policy

This Low-Budget Alternative to C-Stands Could Save You Hundreds of Dollars

Few filmmaking tools are as ubiquitous and multifunctional as the C-Stand. From mounting lights at any conceivable angle to flying modifiers/flags,C-Stands have literally hundreds of uses on a film set. The only problem: C-Stands are not cheap. At roughly $150 a piece -- and that's for the cheaper models -- C-Stands aren't something to whichlow and no-budget filmmakers have constant access. Luckily, there are some significantly less expensive alternatives out there that can provide much of the same functionality at a fraction of the cost. Scott Eggleston over at the Frugal Filmmakerhas one such alternative that he'd like to show you, and it will only set you back $20.

So there you have it, a quick guide for coaxing C-Stand functionality out of a $16 microphone standusing only a few basic accessories, most importantly the 1/4-20 to female mic stand adapter, which opens up an entire world of possibilities for what can be mounted to the end of the stand. This is an absolutely fantastic way to replicate some of the practical uses of a C-Stand without having to shell out more money than you're willing to spend on grip equipment.

As a note of caution, however, despite the fact that a setup like this one might be incredibly useful for mounting and flying lighter items such as microphones, portable LEDs, and small modifiers, it certainly won't replace traditional C-Stands for safely holding heavier objects. Mic stands are not made to hold the amount of weight that C-Stands are, so in order to maintain a safe set, you'll want to avoid mounting heavy lights or modifiers to a stand like this, especially if you're mounting them at the end of the extendable arm.

As with all stands on a film set, it's important to practice proper safety techniquesby weighing down the stand with a sandbag, and making sure that weight is on the opposite side of the stand from whatever you have mounted to it.

Another thing that's worth mentioning is that C-Stands are an absolutely fantastic investment if you're serious about making a living in either video production or studio photography. Unlike cameras and other pieces of digital technology, C-Stands will never become obsolete. Additionally, most of them are literally built like a tank, and should last you for many years.

Link: The Poor Man's C-Stand -- The Frugal Filmmaker

DIY C-stand plans..

Sorry if this has become an old issue but I just saw it and felt the need to add my opinion.

I agree that on set there is nothing better than the use of reliable and trustworthy, professionally made C-stands, upon which you can rely to do the job safely. I must say however that a few years ago I built some DIY C-stands to my own design which I have used many times on set which much success.

I admit the design in the link above is unsafe and flawed and I wouldn't trust it with any of my crew who's safety and welfare I'm responsible for.

I should add though, I used to be an engineer and with that background comes the knowledge of what metal structures will hold a massive weight and what will fall over or collapse etc. So in short, unless you know what you're doing, I wouldn't put the well-being of yourself and your crew in the hands of any DIY design, I wouldn't even trust someone else to build my own design for those very reasons.

But that's just my opinion, not the undisputed law of the universe.

Modern DIY C Table

In this post, Im sharing how to build a unique, modern DIY C-Table from just one 1x6x8 board!

This little table is such a fun and unique design that would be the perfect side table, accent table, or even a simple plant stand.

I played around with both design and color with this little tableas you can see. But if you like to keep things more neutral, this would also look great with a black or white base, too!

Since its such a small project and its assembled in sections, its a great opportunity to get creative with it. Customize the size and color to match your own style.

If youre ready to see how to build it from JUST ONE BOARD, lets dive in.

*This post contains affiliate links. See website policies.

What Youll Need

What to know before building

You should be able to complete this build in a few hoursmost of which is spent waiting on glue to dry haha.

This project is not difficult, but the angles may seem a big confusing. Dont let them intimidate you!

All angles in this project are 10 degrees to keep things simple.

Assemble with Pocket Holes or Dowels

You can assemble these pieces using pocket holes or dowels. Either would work fine.

Overall dimensions:

The overall dimensions of this small DIY C-Table is 16 diameter x 20 tall.

Want to be the first to know about new projects and plans? Join our newsletter for priority access to new posts, tips, and projects!

How to Build a Modern C-Table

If you prefer to watch, Ive got a complete build video on my YouTube channel here:

Are DIY project videos your thing? Subscribe to my YouTube channel for the latest project videos, bloopers, and behind the scenes action.

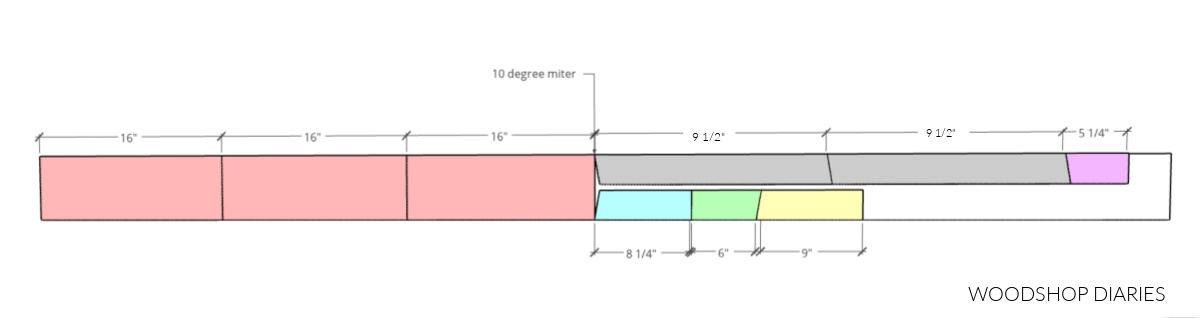

Step 1: Cut C-Table Pieces

First, I cut three 16 long pieces from the 16 board to glue up for the table top in step 2. I set these aside for now.

I ripped the remaining 16 into two 2 wide strips (which makes them 1x3s) using a table saw. If you dont have a table saw, you can CAREFULLY use a jig saw or circular saw and straight edge to rip these instead.

From these 2 wide boards, I cut the following pieces:

- (2) 19 with ends mitered 10 degrees

- (1) 5 with one end mitered 10 degrees

- (1) 6 with one end mitered 10 degrees

- (1) 8 with one end mitered 10 degrees

- (1) 9 with one end mitered 10 degrees

Step 2: Assemble Table Top

To make the table top, I simple edge glued the three 16 long pieces together to make a panel about 16 x 16 .

You can use dowels, biscuits, or pocket holes and screws to join these boards, but just wood glue and some time in the clamps works just fine.

RELATED: How to build a table top

Once the glue had dried (refer to your specific glue type and environmental factors for dry times), I removed it from the clamps. You can keep this table top as a rectangle if youd like, but I wanted mine round.

So I found the center, drove a screw in, and used a tape measure to draw a circle with diameter about 16 (or slightly less). Check out this post to learn how to draw a perfect circle in any size.

I used a jig saw to carefully cut out this circle, then sanded it well and set it aside.

TIP: When cutting circles using a jig saw, its difficult to cut it PERFECT. Thats okay! I recommend cutting a little outside the line, then using a sander to smooth it out and remove the material just up to the line.

Or, if you prefer using a router to a jig saw, you can make a circle jig for your router and cut it out that way instead.

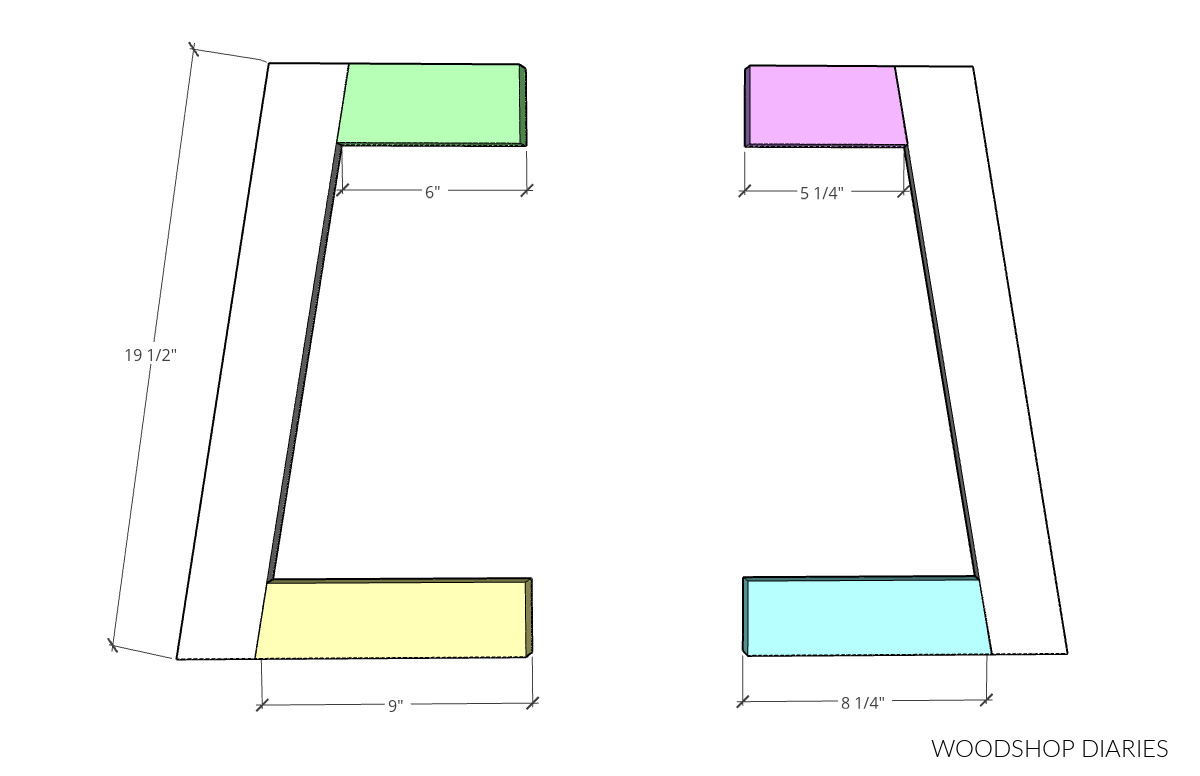

Step 3: Assemble Table Base

The table base is made up of two separate pieces. One short and one long piece attach to one leg. And another short and long piece attach to the other leg.

You can attach these pieces using pocket holes or wood glue and dowels (see notes above). I used wood glue and dowels because I didnt want to see the pocket holes in the finished project.

You can always plug your pocket holes if you dont want to see them, but I didnt have any oak plugs to match the oak I was using here.

But its important to make sure that the 5 and 8 pieces are attached to one leg. And the 6 x 9 pieces should be attached to the other leg.

Once these two assemblies were made, I attached them together to complete the table base.

I just added a bead of wood glue and butted the short side up to the long side and clamped until dry.

My base seems to be holding up well with just glue. However, if you want some additional holding power besides glue alone, a couple finish nails or screws at the joint wont hurt.

NOTE: If you want to finish your pieces in separate colors, apply finish BEFORE attaching them together. This will make it much easier than trying to stain/paint them different colors after theyre glued up.

I stained my table leg assemblies separately with Minwax Water Based Solid Wood Stainone was Early Spring and the other was Royal Pine.

Step 4: Attach Table Top to Table Base

Once the table top and table base are both assembled, the last part is simply putting them together to complete the table!

There are several ways to attach the top to the base. An easy option is simply using 90 degree corner bracketsattach one end to the table base and the other to the underside of the table top.

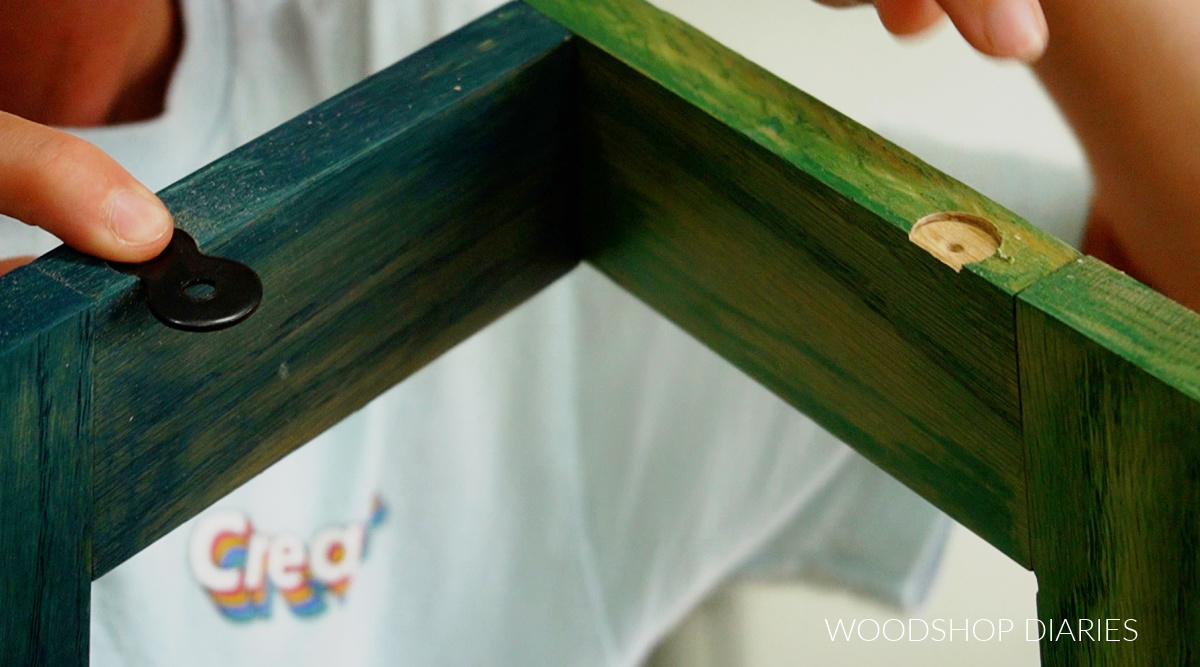

Using figure 8 fasteners is another option and thats what I used in this case. Figure 8 fasteners are a simple way to attach a table top to a base and still allow for wood movement.

I used a forstener bit to drill two very shallow holes on the top of the table base. These should be just deep enough that the fastener sits into them and is flush across the top.

Then I chiseled out the edges a little so that the figure 8 fastener is able to swivel in these holes. I secured the fasteners to the base with two small wood screws.

Then I flipped the table top upside down on the workbench and centered the table base upside down on it. I secured the fasteners to the top with two more small wood screws.

Step 5: Finish and Enjoy

And at that point, the assembly is complete and all thats left is the finishing. I had already stained the base, but I applied a couple coats of Minwax Polycrylic Semi-Gloss to the top and the base to seal it and give it a little shine.

Once this was dry, this little DIY C table was ready for use! This makes such a fun little plant stand table, side table, or even a simple minimalist nightstand.

You could even use it as a stool!

No matter how you plan to use it, I hope you enjoyed watching how it was made!

Looking for more project ideas?

Cant get enough scrap wood projects?? Im teaming up with my friend, Kati, fromHouseful of Handmadeall month long to share someScrap Wood Summer Projects!

Check out all the projects in the series so far below. Click on an image to learn how to make each one!

We will be posting new Scrap Wood Summer projects every Tuesday through the month of August (2023). Check out last years Scrap Wood Summer projects plus other scrap wood ideas here.

Want to save this DIY C Table project for later? Dont forget to pin it or share to your favorite social channel!

Looking for more DIY projects? Here are a few more one board builds youll enjoy!

And if youre looking for similar projects, here are few more small table projects youll love!

Until next time, friends, happy building!